Cost by using our Reliable Fixtures

Clients. Our vast experience of working with various OEMs and MNC Tier 1 Customers will

make Die Makers fixture manufacturing process hassle free.

Cost by using our Reliable Fixtures

Deliver on time, to enhance the development process, making life easy

for Tier 1 Automotive Suppliers.

Cost by using our Reliable Fixtures

to Design and Manufacture large size fixtures in large quantity for the Automotive

OEM customers. We guarantee you we can reduce your import bills.

Cost by using our Reliable Fixtures

metalic BiW assembly Checking Fixtures for Line Builders in large quantity

with assured deliveries.

Tara Tools is a leading BIW fixture manufacturer in India since 2006. We Design and Manufacture Welding Fixtures, Robotic Cells, Checking Fixtures, Attribute Gauges, Assembly Checking Fixtures, Panel Checkers, CMM Holding Fixtures and Auto Gauging Solutions for the Automotive OEM’s and Tier 1 Auto Component Suppliers in India and Abroad. A highly motivated team with a Customer Centric approach is the main strength of Tara Tools. Our thrust on continuous improvement has helped us in delivering solutions of world class standards to global Customers such as Honda, Suzuki, Faurecia, Mahindra, Tata Motors, Gestamp,CIE Automotive etc.

Products and Services

- Fixture Designing

- Panel Checkers

- BIW Assy Checking Fixtures

- Checking Fixture of Plastic Interior

- Autogage

- CMM Holding Fixture

- Testing Fixture

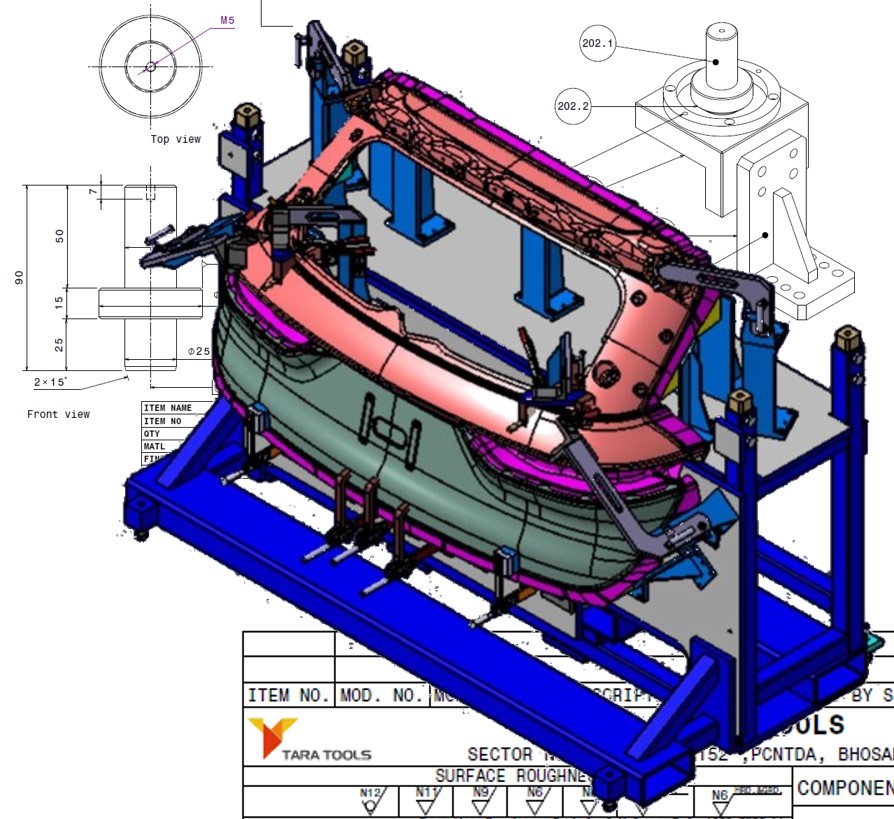

Fixture Designing

Tara Tools provide Fixture Design Services worldwide.

We have experienced team of 14 Design Engineers who are experts in 2D & 3D design of Panel Checkers/ Inspection Gauge, BiW ASSY Checking Fixtures, Checking Fixtures for Plastic Interiors, CMM Holding Fixtures, Testing Fixtures (Vibration/ Heat/ Load), Autogage, etc.

Our Design Engineers can work on site at customer place, globally.

Tara Tools is equipped with latest CAD software's such as CATIA, Unigraphics NX & AutoCAD. We have successfully provided design services to Kyoei INC Japan, Valiant TMS, Nagata India.

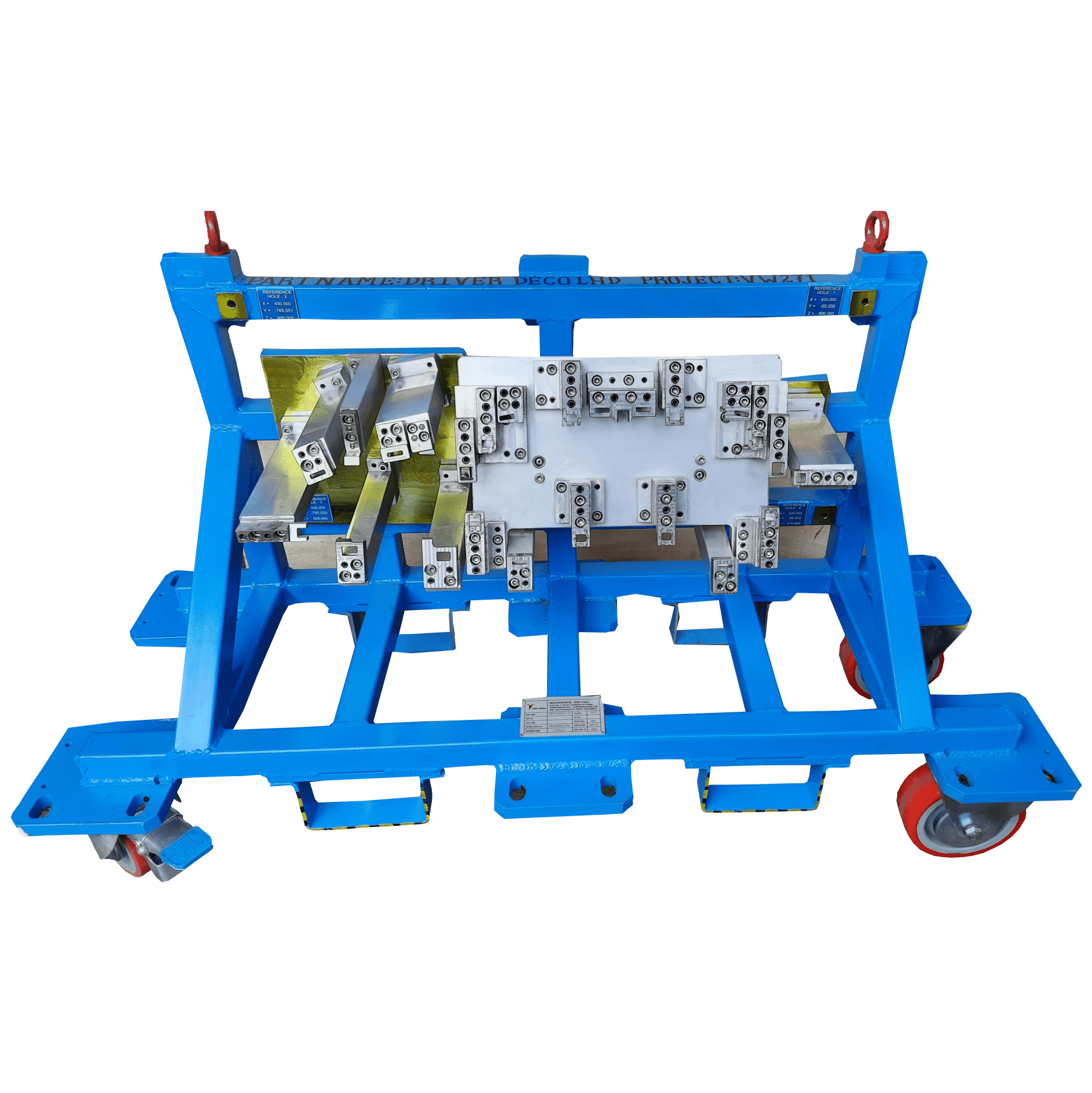

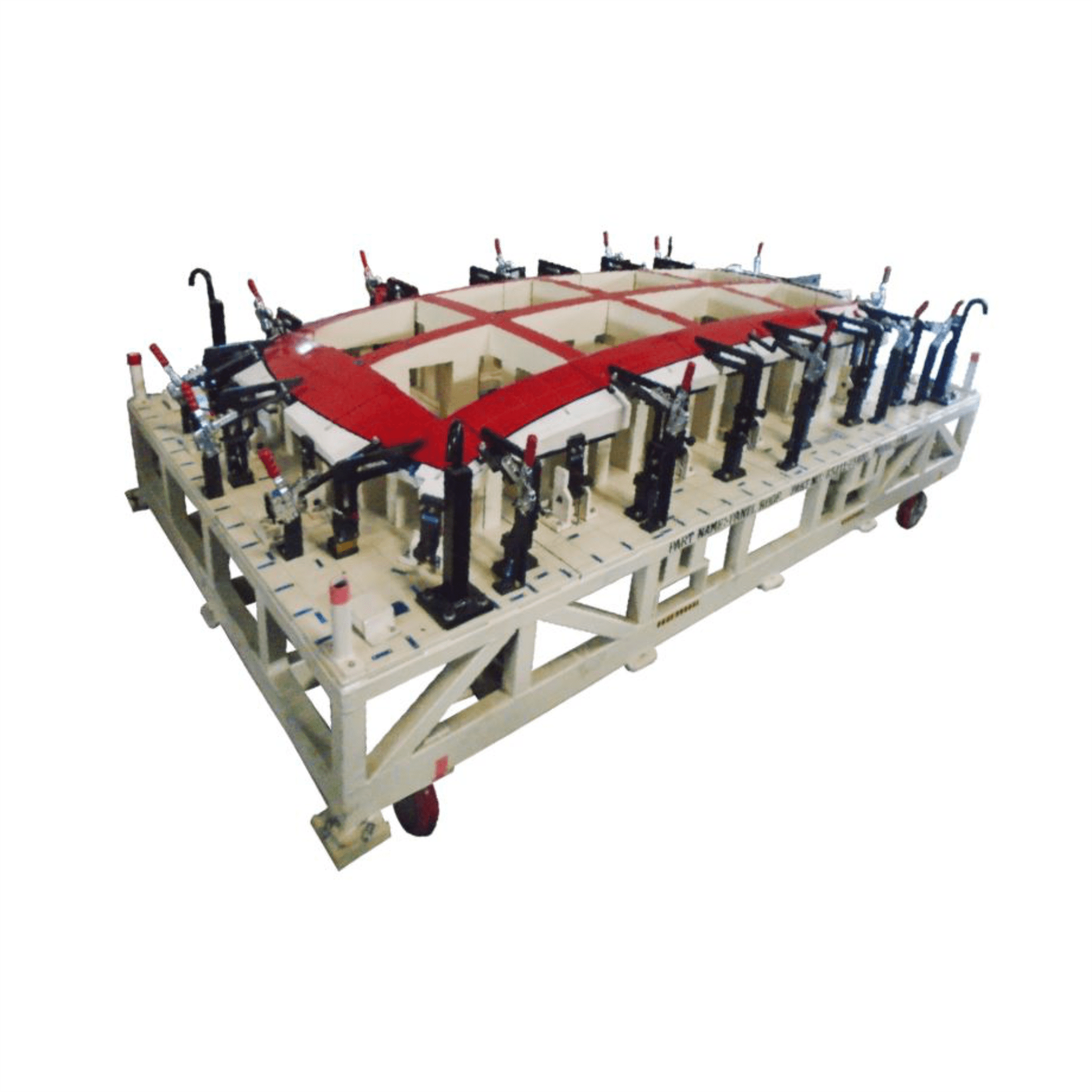

Panel Checkers

We design & manufacture Inspection Gauges/ Panel Checkers for checking Sheet Metal Stamping Parts. These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.

We have manufactured Gauges for small bracket of size (50x50x50) to large panels like Roof/ Door of size (2200x1200x250).

In Last 10 years Tara Tools have manufactured around 2000 gauges for Sheet Metal Stamping Parts.

These fixtures are manufactured using Poly Urethane Board of various densities, Aluminium, Tool Steel. Fixtures are calibrated on CMM machines.

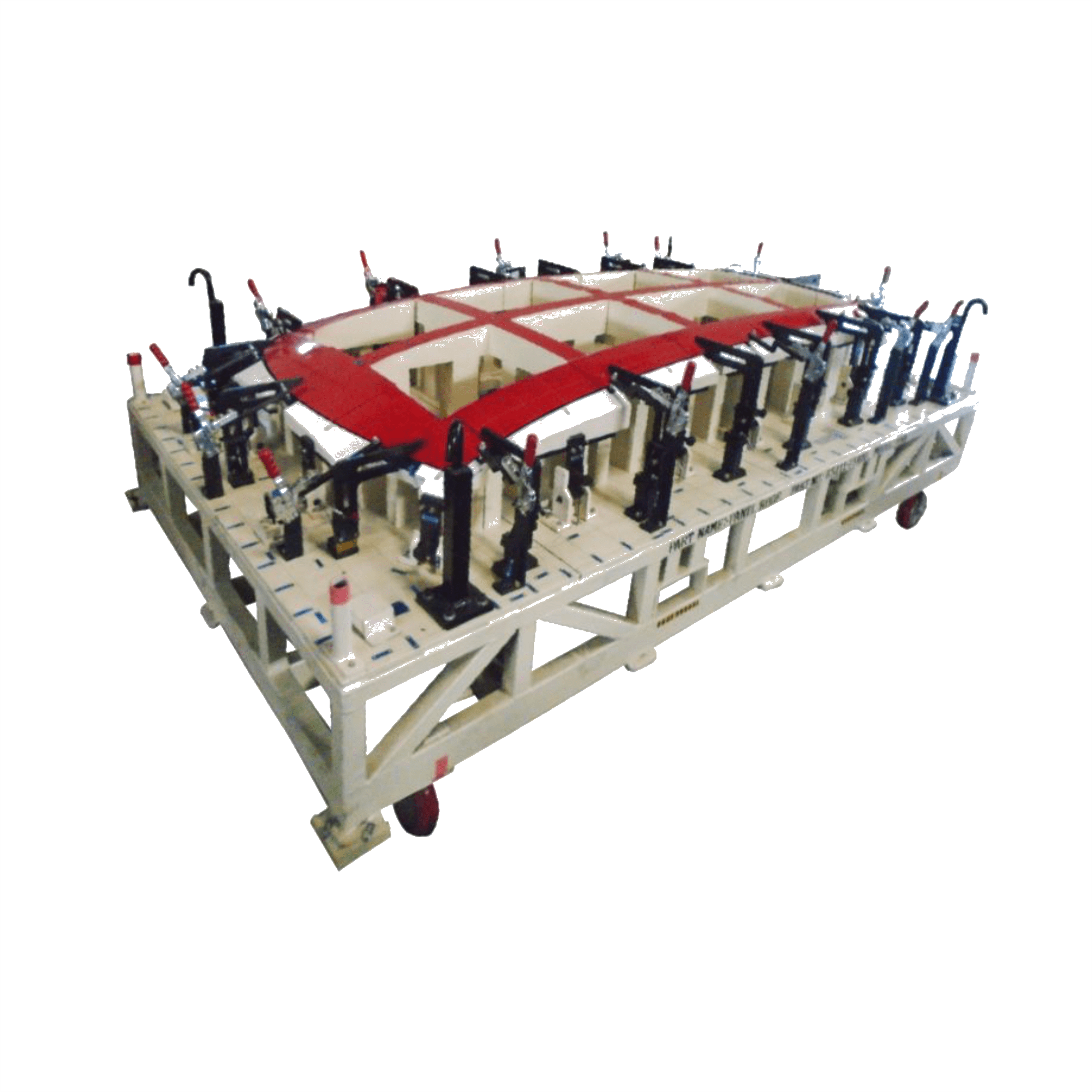

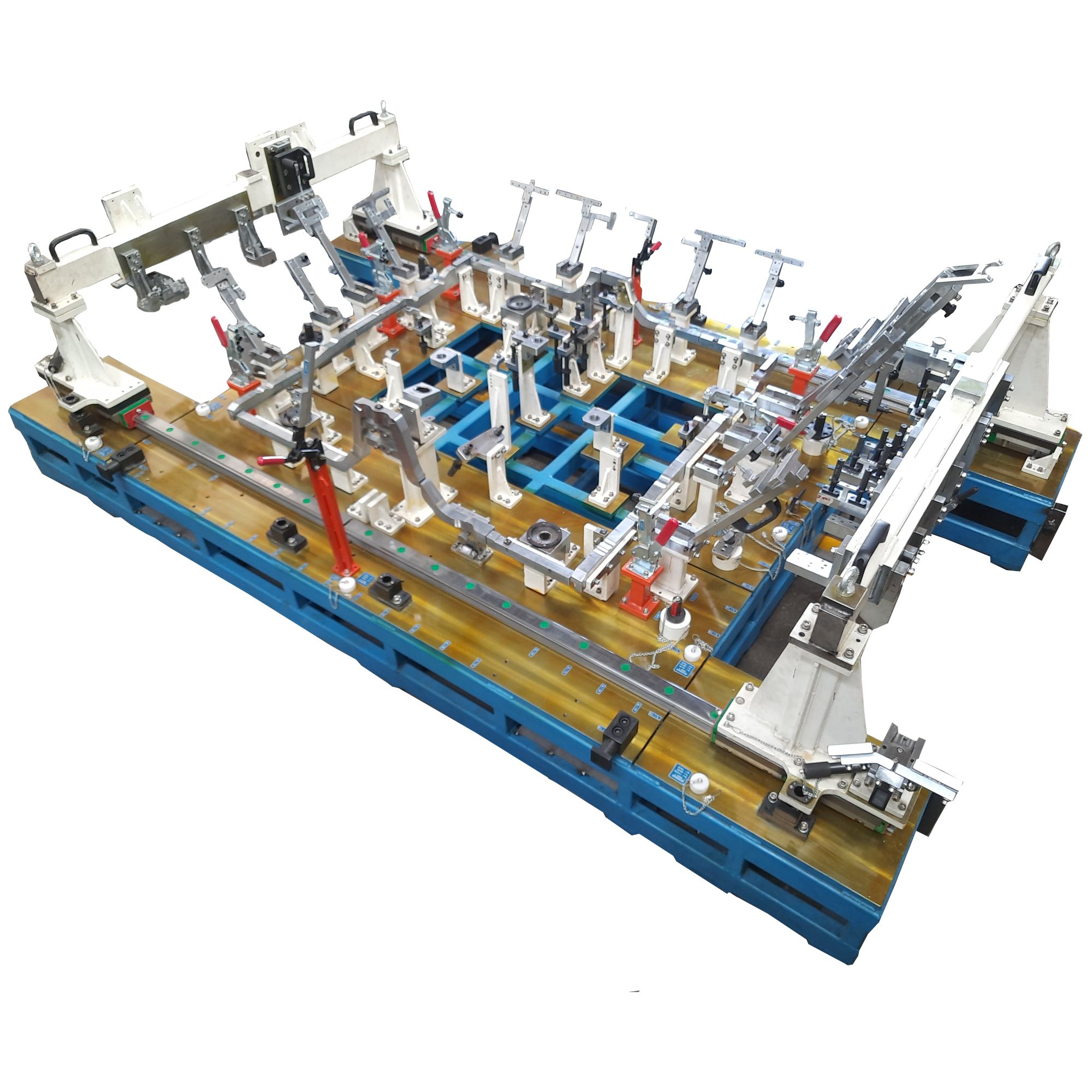

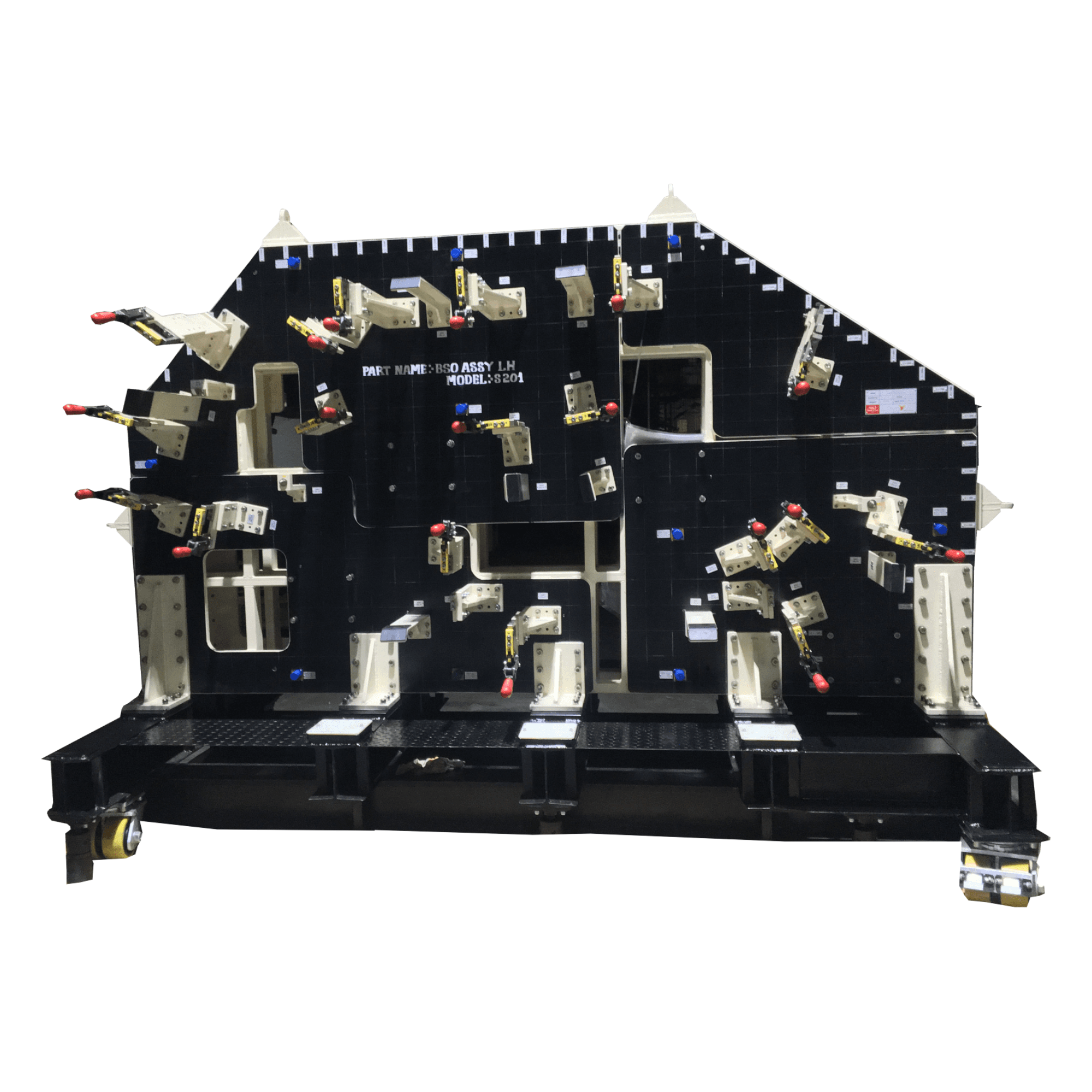

BIW Assy Checking Fixtures

We design & manufacture Checking Fixtures/ Gauges for checking Sheet Metal BiW Assemblies after welding. These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.

In Last 10 years Tara Tools have manufactured around 500 gauges for Sheet Metal BiW Assemblies.

Fixtures are calibrated on CMM machines.

These fixtures are manufactured for BiW Line Builders, Tier 1 Suppliers & OEMs.

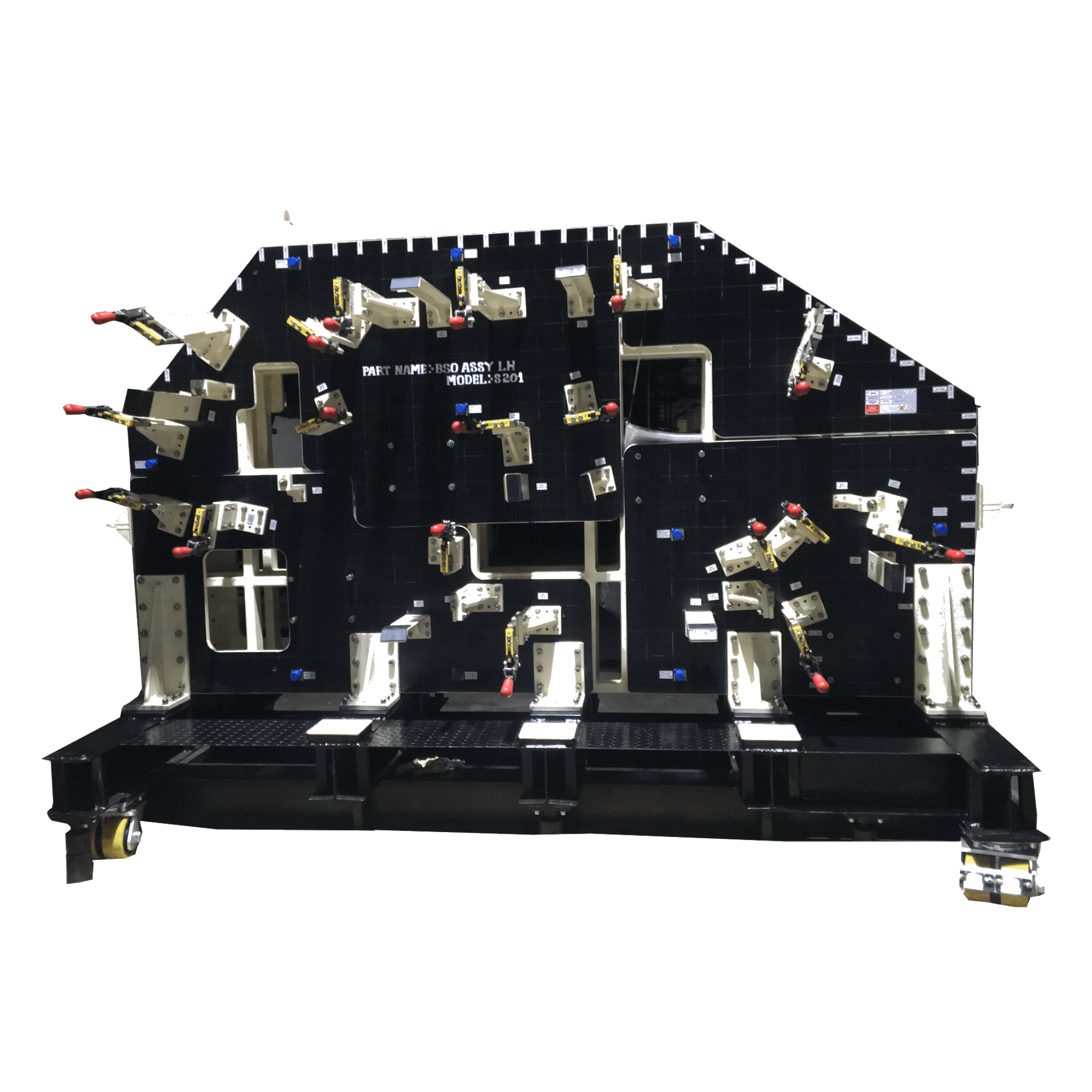

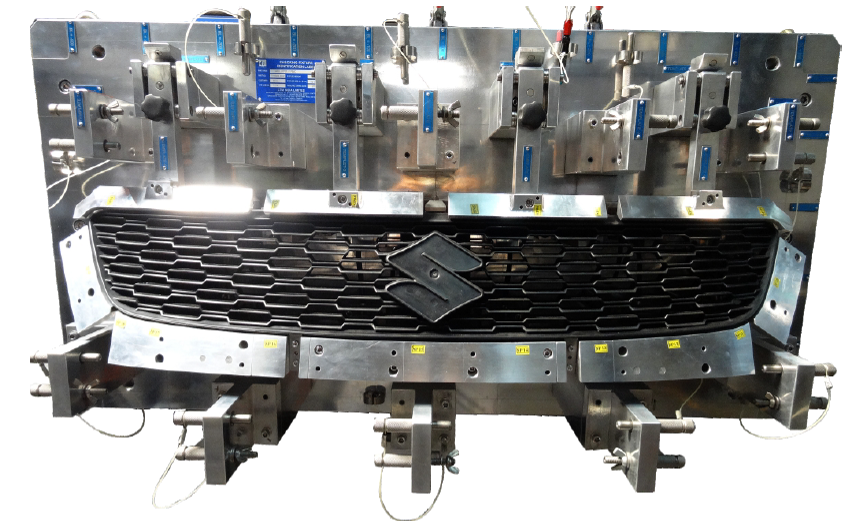

Checking Fixture of Plastic Interior

We design & manufacture Checking Fixtures/ Gauges for checking Plastic moulded parts such as Instrument Panel Substrate & ASSY, Door Panel Substrate & ASSY, Console ASSY, Front Bumper & Rear Bumper, & Child Parts of Instrument Panel/ Door Panel/ Console, Head Lamp, Tail Lamp.

These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.

In Last 10 years Tara Tools have manufactured around 1000 gauges for checking of Plastic Moulded Parts.

These fixtures are manufactured using Poly Urethane Board of various densities & Aluminium.

Fixtures are calibrated on CMM machines.

We have exported these fixtures to France, China, Sweden & Thailand.

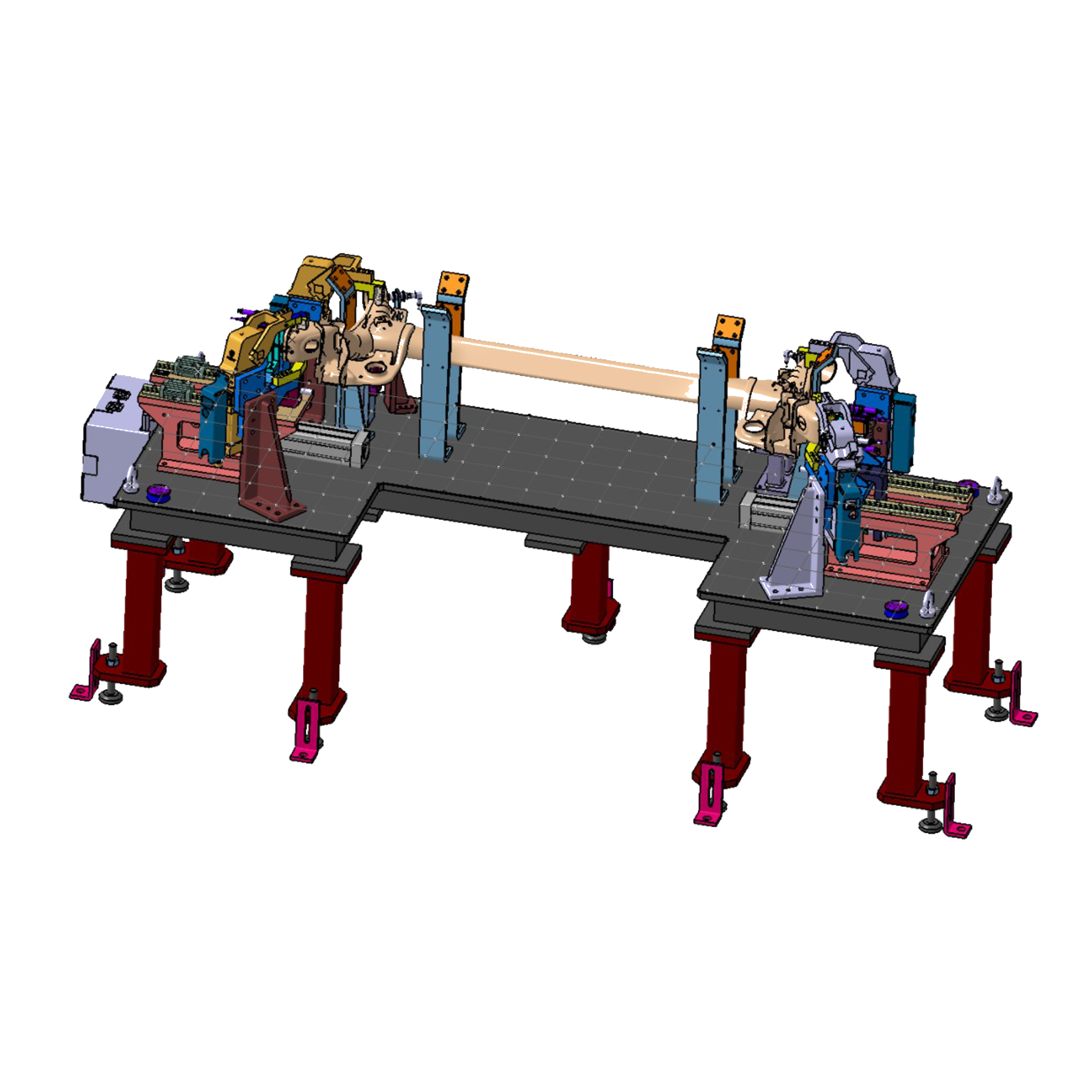

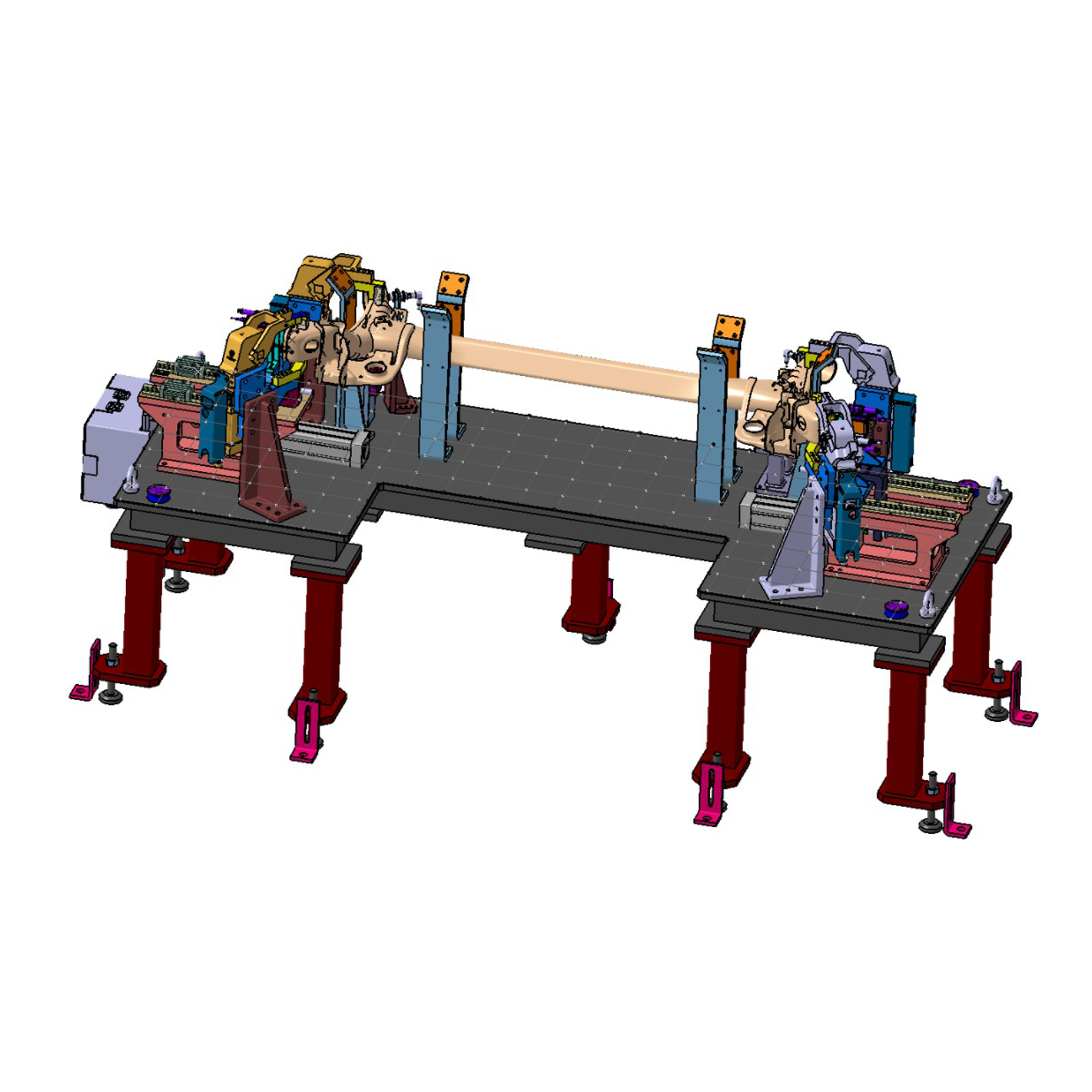

Autogage

We design & manufacture Auto Checking Fixtures/ Gauges for checking of the part where 100% inspection is compulsory. These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.

We have manufactured fixture for checking Camber & Toe Angle of Rear Twist Beam & fixture for checking holes position of Cross Car Beam.

These fixtures are equipped with PLC Controls, Sensors, Pneumatics, Barcode Scanner & Engraving Machines, etc.

CMM Holding Fixture

We design & manufacture CMM Holding Fixtures/ Gauges for holding Sheet Metal Parts, Plastic Parts & Assemblies. The purpose of fixtures is to hold the part in Carline position while checking on CMM machine/ Laser Scaaning. These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.

Testing Fixture

We design & manufacture Testing Fixtures for holding Plastic Moulded Parts & Assemblies. The purpose of fixtures is to hold the part in Carline position while doing Vibration Testing, Impact Testing, Heat Testing. These fixtures are manufactured as per the Customers Fixture Standards/ Specifications.